Manage Your Soy Extrusion and ExPress ® Process: New Insta-Pro Portable Ingredient Analyzer (PIA) NIR

What goals do you have in your extrusion plants? What metrics do you use to know if you’re achieving these goals? How do you obtain the values used in your performance metrics?

If you ask yourself these questions, there is a good chance that you are interested in maximizing oil extraction from your soybeans. A quantity of isolated oil is more valuable than the same quantity of soy meal – sometimes worth greater than twice the price.

In addition, an extrusion/oil pressing (ExPress®) soy plant produces, by far, more soy meal than oil by output weight. ExPress® soy meal and dry extruded whole soybeans (or extruded full-fat soy), when properly processed and used in an appropriate formulation, have long been shown to produce superior animal performance compared with diets containing commodity ingredients (see here, here, here, here, and here).

However, every nutritionist, ingredient broker and animal producer will tell you that they demand one main thing – ingredient consistency. How do you know if your ExPress® soy meal has 44% crude protein and 7% residual oil or 45% crude protein and 6% residual oil? A nutritionist will formulate a diet differently with these two soy meals. An ingredient broker will pay (and sell) differently for these two soy meals. And, the animal producer may see different results (feed efficiency, milk production, body weight gain, carcass characteristics, etc.) with these two soy meals.

In short, if you’re not producing soy meals with very similar nutrient contents time after time, you’re not manufacturing the same product each time. And fewer people may want it.

And, to add to the complexity, characteristics of your initial soybeans affect the resulting meal, too, and also oil isolation efficiency. Are your beans 14% or 10% moisture? Are they 7%? The extruder may need to be configured or operated differently based on raw bean moisture content. Also, when trying to extract as much oil as possible, do your beans have 17% or 23% oil? Or somewhere in between? You can’t isolate something that is not there, and higher-oil beans may require a different extruder configuration – especially if moisture is high, too.

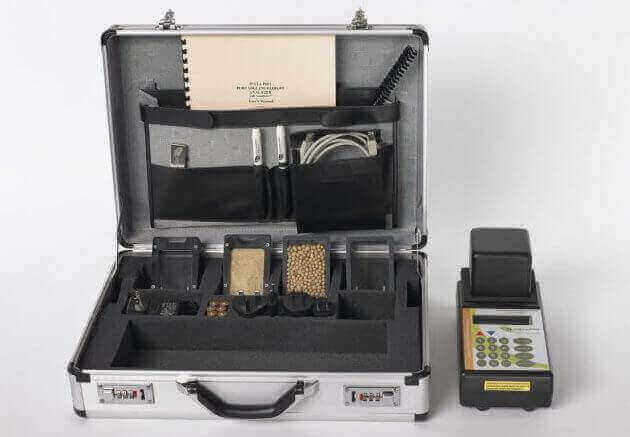

At Insta-Pro, we are committed to helping you get the best results from your plant. We have developed the Insta-Pro Portable Ingredient Analyzer (PIA) NIR machine – a new tool, specifically for you, to help.

Near infrared (NIR) analyzers have long been recognized by the food and feed industries as machines capable of predicting nutrient values in intact samples. The results can be obtained in a matter of minutes. So, they are very useful in a production facility – a sample can be taken off the line and results gathered right away, allowing nearly real-time adjustments on the plant floor.

But, all NIR machines must be calibrated in order to predict accurately, and we’ve done this for you. Hundreds of soy samples from Insta-Pro equipment were taken, analyzed by a lab and used to build proprietary calibrations. This means that you can buy an Insta-Pro PIA and use it immediately.

The Insta-Pro PIA NIR machine will predict moisture, protein, oil and fiber in whole soybeans, ground extruded full-fat soy and ExPress ® soy meals. In addition, oil cake samples from individual presses can be taken and ground for these analyses – allowing instant feedback on individual oil press performance.

For more information, contact me, Dave Albin (dalbin@insta-pro.spinudev.com or 515-419-2231), about the new Insta-Pro PIA NIR machine and learn how it can help you optimize quality in, and meet the goals of, your soy operation.