MORE RESIDUAL OIL DOESN’T ALWAYS EQUAL MORE ENERGY FOR GROWTH

Last year, I wrote a blog series which concluded that choosing ingredients with more high-quality residual oil in the meal could add many benefits to your formulation program. The final post, as well as links to the others, can be found here.

But, is more always better? Is it possible to have more residual oil in the meal, and have this actually be detrimental?

It’s clear that fats and oils are energy rich – per unit mass, oils provide more energy than either carbohydrates or proteins. Often, a small percentage of fats or oils are added to complete animal diets in order to increase the amount of metabolizable energy (i.e., usable for growth) and maximize growth performance. Indeed, high-shear dry extruded/mechanically pressed (ExPress®) soy meal, with 6-8% residual oil in the meal, has higher metabolizable energy than solvent-extracted (completed deoiled, < 1% remaining), commodity soybean meal. The main reason is due to the oil composition of the meals. Other reasons include thorough rupturing of plant cell walls by high-shear dry extrusion, as well as partial dehydration (also via extrusion cooking), which concentrates nutrients and energy.

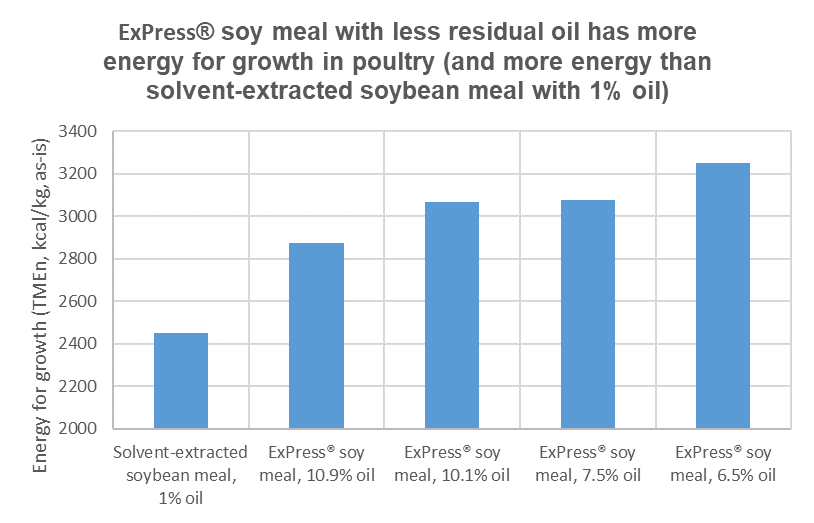

But, as shown below, using data taken from this study, this relationship starts to fall apart at higher residual oil levels (data for solvent-extracted soybean meal is included for comparison purposes).

What’s going on here? As residual oil levels decline from 10%+ to about 6%, metabolizable energy in poultry increases.

The answer lies in all the benefits of high-shear dry extrusion, mentioned above. As soy is properly processed in a high-shear dry extruder, it’s exposed to more pressure, greater shearing forces, and elevated temperature – but only for a matter of seconds, maintaining and enhancing the qualities of proteins and other nutrients. Also, as shown above, more oil is removed from the raw beans (and this is good because oil is more valuable than soy meal per unit mass) in the mechanical oil press.

With proper high-shear dry extrusion processing, plant cell walls are thoroughly ruptured, and more moisture is lost through dehydration. Both effects increase the usable energy in soy meal for poultry, and other animals as well.

The opposite is true, of course – improper processing of soy via ExPress®, or the use of an inferior mechanical process (lacking in adequate temperate, pressure, and shearing forces for proper cooking) will result in greater residual oil in the meal, and reduced energy for poultry, in the final soy meal. It should also be mentioned that the use of raw soybeans with very high levels of oil could also cause residual oil levels in meal to drift upward.

In short, properly processing soybeans with high-shear dry extrusion and mechanical oil pressing from Insta-Pro improves both the quality of your products, and your bottom line by having more oil (and better meal) to sell. Speak with us today. Make sure you’re getting everything you can out of your ExPress® soy plant.