Insta-Pro’s ExPress® Process – Oil with a Long Shelf Life

The high-shear dry extrusion process, followed by mechanical pressing for oil extraction, is a decades-old, globally accepted set of equipment and processes. Oilseeds, most commonly soybeans, are used as the raw material to produce high-quality, protein-rich meal and oil. As with any mechanical oilseed process, some oil will remain in the meal – between 6-8%. Residual oil is natural and depends upon the initial raw material oil content, the adequacy of the parts, and how the process is performed.

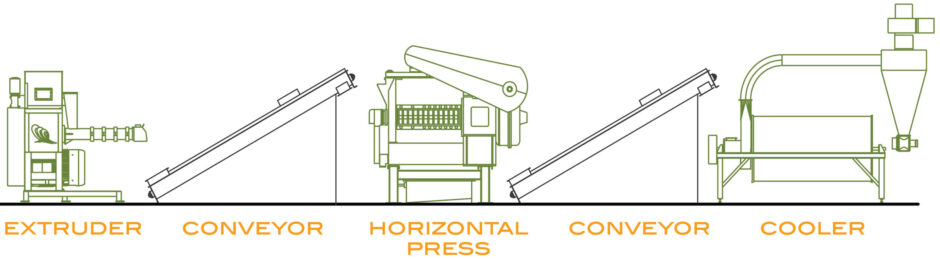

So how is the entire ExPress® process run to maximize the shelf life of the residual oil in the meal? It’s important to understand that dry extrusion can be thought of as a continuous pressure-cooking process. If you do not have the right equipment, or the equipment is not used correctly, product quality will suffer. Improperly produced meal and oil will become rancid more quickly.

To create meal with a long shelf life, the first important step is to use raw soybeans within the ideal moisture range, 9-11%. Too much moisture will inhibit friction, and too little moisture might make it more challenging for the extrusion process to do its job deactivating antinutrients such as enzymes. These naturally occurring enzymes speed up the rate of rancidity of oils, so proper extrusion cooking is essential to stop most or all enzyme activity. On the topic of moisture, the dry extrusion process flashes off moisture, roughly 50% when run at the proper, higher processing temperature. Less moisture promotes the stability of oil. Higher extrusion temperatures are also needed to commercially sterilize raw soybeans effectively. A lack of viable microorganisms, such as bacteria and viruses, will also promote a longer shelf life.

The dry extrusion process is, by design, a short-time process. This is also important for oil stability. Rancidity can happen when too much heat is applied to oils, but the dry extrusion process lasts less than 20 seconds, and the highest extrusion temperatures are experienced for only about 5 seconds.

Analysis of the shelf-life of ExPress® has indicated that ExPress® ingredients, which contain residual oil, will last considerably longer than other meals. A recent study from Iowa State University concluded that even under prolonged high temperatures of 140°F (60°C), ExPress® could be stored for up to 12 months without significant rancidification to its oils. This means that unlike other fat sources, which may become rancid in only a couple of months, rendering the meal unusable, ExPress® can be kept for long periods without the worry of its nutritional value deteriorating.

Get in touch with our nutrition team for more detailed information.