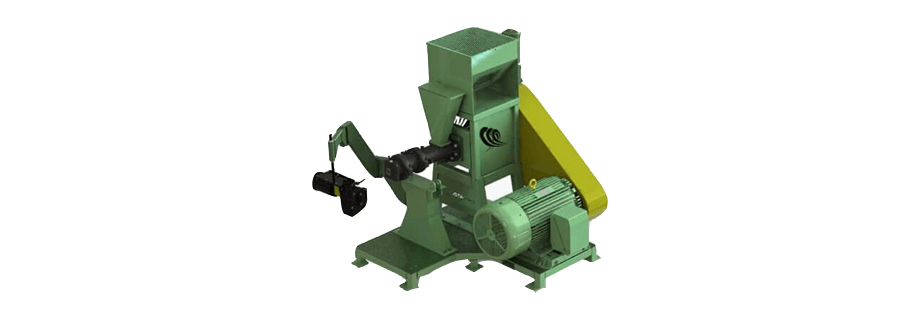

The Extruder Shop

This post will cover some of the additional tools and equipment that are often overlooked when extrusion plants go into operation.

This is especially important for the producer that is new to extruders and oil presses. Larger, established companies usually have existing shops with everything necessary, but the smaller, first-time extruder owners are unprepared. This isn’t any fault of theirs; they just don’t know what to expect.

I also like to point out that a lot of the tools are necessary at the time of start-up. It can frustrate everyone involved in the start-up process and they can be wasting time scrounging for tools that could have already been on site.

After starting up plants for a couple of decades, I can tell you a carpenter hammer, universal wrench, and pair of vice grips aren’t going to get the job done. At start-up time, it often takes a day or two to sort out all the bugs in the electrical system. This can mean that for whatever reason, the extruder and/or press can shut down under a load. This requires dismantling the equipment to quickly clean it out.

In the future, a power failure will cause the same problem. A machine that goes down full comes apart more easily when it’s still hot. It’s never easy, but looking around for tools for 30 or 40 minutes will just make it harder. I’ll try to separate the list into two parts (tools you can’t live without and tools you will be really glad you have).

Tools you can’t live without:

- A set of good quality screw drivers

- A full set of end wrenches

- A screw puller

- A set of hex head (allen) wrenches

- Vise grips and pipe wrenches

- A good quality set of socket wrenches (1/2” drive)

- Several sizes pry bars

- Two or three sizes of heavy hammers

- Two or three sizes of dead blow hammers (the dead blow hammers will prevent damaging the cast parts on the machines)

- A good set of chisels and punches

- An oxy/accetelean torch (for cutting and heating)

- A drill and 3 inch angle grinder

- Several lengths of hard 4×4 wood blocks (again, to prevent damage from hammering)

- Air compressor (big enough for impact tools)

- Impact wrench (include a ¾” adaptor if you have an oil press you’ll know what for)

- Die grinder

- Chain wrench

- 30 ton press

- 2 ton chain hoist

- Porta-power

- Log chains

- A fork lift or motor hoist.

Remember, all of these tools will be used on not only the Insta-Pro equipment, but also the support equipment. One other suggestion for the people with oil presses is to have a moisture tester on hand for testing the raw material.

As always, I would be glad to hear any other ideas or thoughts on this or any other subject.