Optimizing Your Corn Extrusion Process

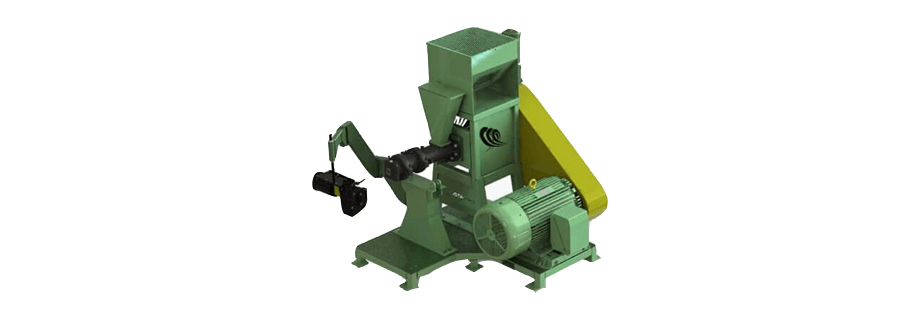

Driven by customer demand, Insta-Pro has developed a processing solution for corn extrusion. Our customers are excited for this as gelatinized corn has been shown to improve efficiency and performance in baby animals. Extruding corn can be difficult to do properly because of its high starch and low oil content. This causes the product to gelatinize and expand, sometimes uncontrollably. Recent R&D work has allowed us to develop a specialized corn extruder which features one processing chamber.

This new development and our best practices help ensure a more stable and efficient process. Even with specialized equipment, there are still recommended procedures to follow which can be applied to all scenarios. These recommendations can result in less wear on parts, lower operator costs, and less downtime for maintenance, leading to increased productivity.

When extruding corn, the high temperatures and pressure cause the corn to gelatinize, making the corn come out of the nose cone in a rope-like form. This results in problems with conveying and storage. A solution for this problem is adding a particlizer at the end to break up the product. If this isn’t used, the rope-like extruded corn can wrap around the auger in the conveyor and plug it. The particlizer should be on a variable frequency drive, so you can control the size of the extruded corn by speeding up or slowing down the particlizer.

Another essential device to have when processing corn is a water injection system that is installed onto the extruder. The blend of starch and low oil, combined with the high friction of the extruder, results in the product becoming unstable and varying in temperature as well as “surging”. Surging is when product builds up in the barrel and with enough pressure built up behind it, the pressure will blow the product out. This process is hard to control and can lead to faster wear and higher parts costs.

A water injection system solves this issue by injecting water into the inlet chamber with the water pump system provided by Insta-Pro. This helps to ease some of the friction and stabilize the extruded corn process. Also, since the use of the particlizer at the end covers the nose cone (where the temperature is controlled), the water injector acts as another form of temperature control. If the product gets too hot, increase the water injection rate. If the temperature is too low, back the water off a little bit.

Extruding corn can be tough, but with the help and resources that Insta-Pro has to offer, such as engineers, nutritionists, and service support, you can have peace of mind. In our experience, we have been able to achieve starch gelatinization of 90+% using the methods and parameters described here.