Larger Equipment is Not Always the Best Choice

I recently spent some time on the phone with one of our customers who operates what most would describe as a small production line for shaped, extruded food products. I was helping them overcome a few challenges they were experiencing, but we also discussed possible future expansion, which became more and more interesting to me as our discussion proceeded.

Is it better to get bigger equipment when growing and expanding your operation? Certainly more production per hour with bigger equipment could have benefits, such as potentially driving down costs of production per hour via increases in volume. However, using bigger pieces of equipment to produce more tons of products per hour requires more capital spending. This includes not only the costs of buying the large equipment, but also the added costs of land and buildings.

Also, a production system must be designed with a particular product and production rate (tons/hour) in mind. If you have only a few, large pieces of equipment, you lose the ability to be flexible in the varieties of products that can be made based on changing market conditions. Deviating from what a piece of equipment is designed to do, or making alterations that have not been recommended by the equipment manufacturer, may make an expansion plan more difficult, if not impossible.

Another approach is to use small machines. Having one, or several identical, smaller production lines, operated and maintained in accordance with recommendations from the manufacturer, is advantageous for many reasons:

- Maintenance is easier and potentially cheaper due to smaller parts.

- There is less risk of worker injury when handling smaller parts.

- As a result, less technical support staff is potentially required.

- Less downtime (due to reasons 1 & 2 above). Downtime, when paying people to not make anything, is expensive. Also, a 10 ton/hour machine is now a 0 ton/hour machine.

- There is room for more flexibility in the varieties of products that can be made in response to changing market conditions.

- It becomes easier to maintain quality production because it is possible to inspect a higher percentage of the total daily production.

- Along these lines, maintaining quality systems is easier and there is a high level of food safety because what happens on a smaller production line can be better understood, documented, and controlled.

- Additional lines can be added as the company grows and is profitable.

- With many lines, production can continue as one line is shut down for maintenance.

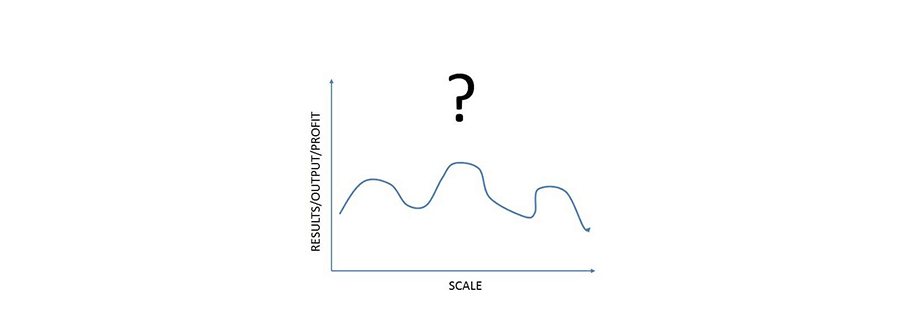

- Scaling up from a small production unit to a larger one is not linear; simply put, the most profitable formula that runs well on the small machine will almost certainly not run the same way on a bigger machine.

In conclusion, expansion in any food or feed business is always a goal, but how to go about it is critically important. I was reminded of this recently during my phone call. Choosing to invest in large equipment often has many consequences. It is often smarter to continue with a larger quantity of smaller pieces of equipment. Be careful not to get in over your head or choose the wrong approach and get stuck with only a few (potentially less than ideal) options.